The word automation first moved into our everyday lexicon around 1946 to define the automobile industry’s growing use of self-moving, pre-programmed machinery in production lines. From there, automation pervaded the production industry, taking over menial physical tasks previously performed by humans. Since its assembly line origins, technology has taken automation in brave new directions—from the factory floor to the office cubicle.

In the 21st century, automation has moved into the office and taken the form of machines that “think” more than they physically move. Industries and businesses outside production and manufacturing are using automation to improve business processes, taking over menial manual tasks previously performed by humans.

Many organizational leaders believe automating business processes can power operational efficiency, improve time-to-market and the customer experience. Industries such as banking, healthcare, and retail are using hyperautomation to take over human-performed manual tasks: file transfers, order entry, claims processing, email, spreadsheet entries, application integration, event log monitoring, cloud enablement—and many more are up and coming.

Business process optimization isn’t just about adding technology; at its core, it’s about first evaluating and improving a process’s efficiency and accuracy.

What Is a Business Process?

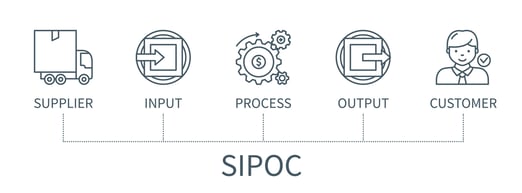

A business process can be defined as a series of distinct functions that an organization uses to complete a targeted task. Though processes vary within different industries at the fundamental level, every business process can be broken down into three steps:

- Accept an input

- Process the input

- Generate an output

Claims processing would be an example of a basic business process: the claims data is received (input), it is processed, and the claim is filed (output).

Should Business Process Optimization Be Automatic?

Most of us are familiar with the adage, “Just because you can doesn’t mean you should.” This saying to can be applied to many situations and actions—and automation for business process optimization (BPO) may be one of those.

And yes, automation can minimize the time and effort it takes a human to perform a task. But if a flawed manual process is simply automated, that faulty step or action will likely continue through the automated process, delivering mistakes or other unwanted results.

Process complexity is also something decision-makers should evaluate before opting for automation. The more complex a process, the more complex the programming, which could produce unrealized errors. Also, more computing time might be needed along with a higher number of updates or bug fixes—which would require more human interaction, i.e., time.

Business process optimization isn’t just about adding technology; at its core, it’s about first evaluating and improving a process’s efficiency and accuracy. The solution is not to forgo automation but to correct a process’s weaknesses and defects first—fully optimize the process.

Here are some common goals for optimization.

Business Process Optimization Goals:

- Streamlined workflows

- Enhanced efficiency

- Clearer communication

- Improved accuracy and consistency

- Elevated customer experience

5 Steps for Business Process Optimization

Let’s take a look at five major steps towards optimization.

- Identify and document your existing process

Define the process’s purpose, goals, and the steps you currently take to complete the process. Be careful of your own inherent biases. What may seem self-explanatory should still be recorded and reviewed. - Identify the systems or tools used to complete the process

What software applications do you use? What steps are done manually, by hand? Is everyone using the same tools in the same way? - Identify all persons involved or responsible for each step of the process

Also, consider if each person’s contribution is the best use of his or her time. Is this function part of this person’s job description? - Analyze the process

Evaluate all aspects of your process. Ask questions, such as: Does the process require excessive resources (time, number of employees, etc.)? Are there known issues like inferior accuracy, poor customer satisfaction, or delayed deadlines? Are there steps you can eliminate? At this stage of your optimization venture, you might consider seeking third-party assistance for a more objective perspective and perhaps more targeted expertise. - Document your revised process

Once you’ve identified deficiencies and faults within your process, lay out a framework for the new process. If you’ve determined that the process will benefit from removing manual interaction, you plan for automation.

If you’d like to dive deep into hyperautomation and how your organization can benefit, visit Genzeon.com.